Sunflag – The Group

The Sunflag Group founded in 1937 in Kenya is today a diversified global conglomerate with manufacturing facilities spread across eight countries and business operations in most others, across the globe.

Set up on strong foundations of business ethics and commitment to quality. the USD 600 million group has emerged as a leader and world-best, in its chosen diversified businesses of Steel Products, Textiles, Fashion Garments, Artificial Leather, Agriculture Agro and Forest based produce, Power Generation, Financing & Project Consultancy. With 20 group companies, the group today employs over 10,000 people.

Sunflag – The Stellar Steel Story

The Group’s focus on engineering competencies has seen it emerge as one of the major players in the steel industry.

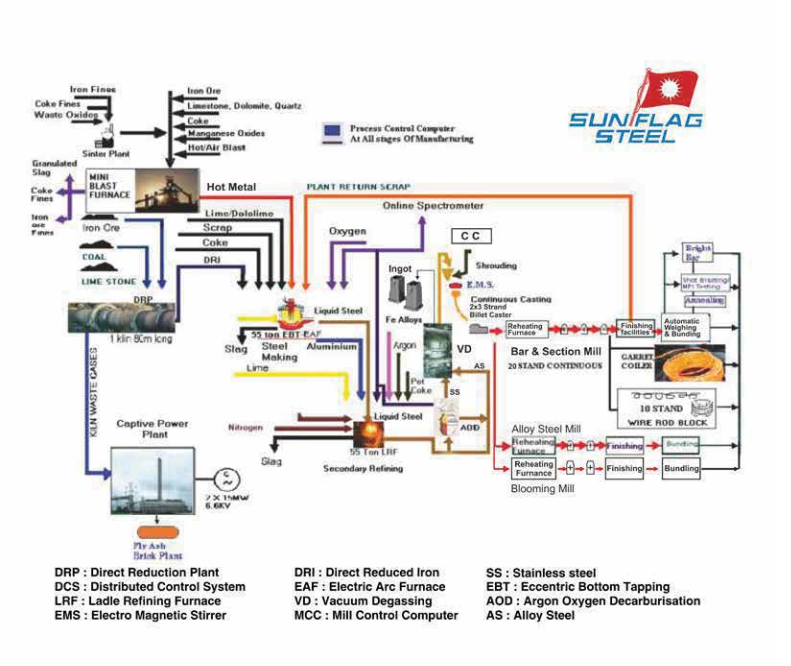

Sunflag Iron & Steel Company Limited, the Group’s flagship company, set up a state-of—the-art integrated steel plant in technical collaboration with Krupp, Mannessmann Demag and Hamburger Stahlwerke, Germany. This is one of the world’s most advanced and integrated steel plants located at Bhandara, India, in verv close proximity to its raw materials and has a capacity to produce over 5,00,000 tonnes per annum of high quality steel of a varied product mix. using iron ore and non coking coal as basic raw materials.

Sunflag Steel today caters to the demand of various core sector industries like automobiles, railways, defense, agriculture, engineering etc. It is approved as an OEM authorized supplier of high quality steel by major companies in India and overseas, including General Motors, for worldwide supplies of their spring steel requirements.

The varied product mix of specialized steel includes a wide range of Carbon Steels, Alloy Steels, Free Cutting Steels, Spring Steels, Ball Bearing Steels, Micro Alloyed Steel, valve Steels & Stainless Steel. These are manufactured in strict confirmation to lndian & International standards like, DlN/ SAE AISI/ ASTM/ EN, JIS. GOST and BIS.

A 30 MW captive power plant using waste gases and coal-fired burners ensures consistent and quality power supply, as well as cost competitiveness.

Stainless Steel

Stainless steel is steel containing 10.5% or more of chromium. which imparts it with corrosion resistant properties,by the formation of an impervious layer of chromium oxide on the surface.

Stainless Steel finds many applications,which include:

- Construction industry

- Boiler industry

- Pumps and Shaft applications

- Flanges

- Surgical applications

- Cutlery

- Weaving and Knitting Wires

- High Temperature Corrosion Resistance Chemical and Petrochemical industries

- Springs etc.

Types Of Stainless Steel

| S. No. | Types of SS | Typical Properties | Broad Applications |

| 1 | Martensitic | High Hardness, Strength with corrosion and Wear Resistance |

Scissors, Shears, Knives, Forks, Medical Instruments, Boiler and Pumps, Cutlery items. |

| 2 | Austenitic | Corrosion resistance Good ductility |

Chemical industries, Utensils, Flat products |

| 3 | Ferritic | Magnetic Properties Corrosion resistance |

Cores of Electrical Equipments, Ribbed Bars, Exhaust systems of automobiles |

| 4 | Duplex | Very High Strength | High Pressure pipeline Parts, Chemical Industry equipments, Ribbed bars for special Applications |

| 5 | Precipitation Hardened | High Strength and Corrosion resistance |

Petrochemical industry |

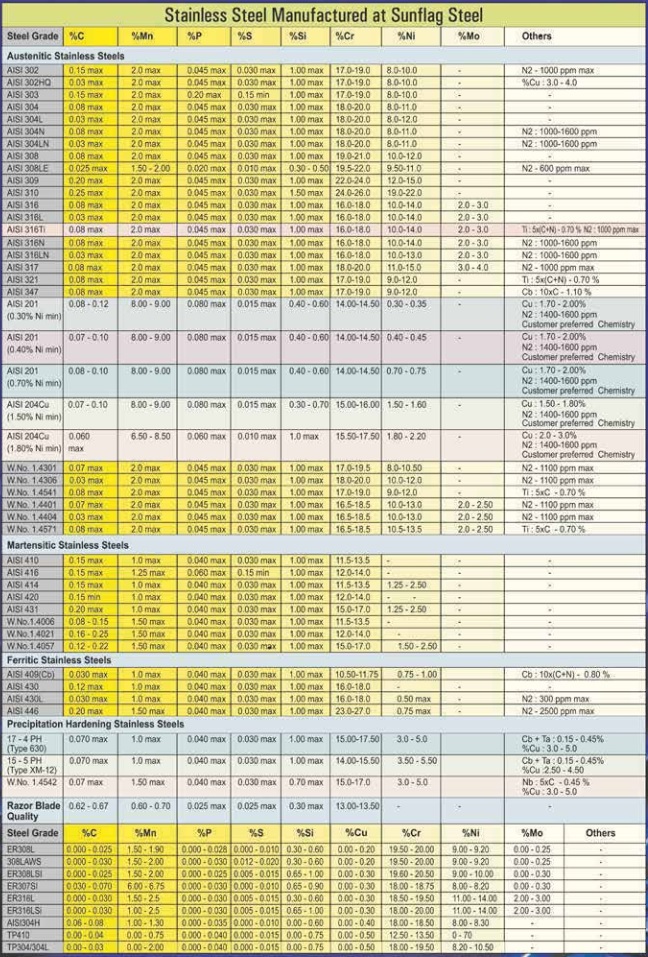

Stainless Steel Manufactured at SunilagSteeI

Similar other grades can be produce with different desigination & chemistries

Stainless Steel Bright Bars

| Cold Drawn and Polished. | CD+ P |

| Cold Drawn and Centreless Ground | CD+CG |

| Rough Turned | RT |

| Smooth Turned and Polished | ST +P |

| Smooth Turned& Centreless Ground | ST+CG |

| Forged and Turned | FT |

Bright Bar Capability

| Cold Drawn and Polished . | 4.5 -32 mm (coil route) 14- 50 mm (straight bar route) |

| Cold Drawn and Centreless Ground | 10 – 32 mm (coil route) 14 – 50 mm (straight bar route) |

| Rough Turned | 15 – 250 mm |

| Smooth Turned and Polished | 15 – 200 mm |

| Smooth Turned& Centreless Ground | 15 – 100 mm |

Stainless Steel Billets-As Cast & Rolled

| Supply Condition | As Cast Spot Ground Four Face Ground Hot Rolled Annealed and Pickled |

| As Cast Billet Sizes | 130 x 130 mm 160 x 160 mm 210 x 230mm 240 x 280mm 280 x 320 mm |

| Rolled Billet Sizes | 50 mm x 50 mm x 6 m 55 mm x 55mm x 6m 60mm x 60 mm x 6m 63 mm x 63 mm 6m 75 mm x 75mm x 6m 80 mm x 80 mm x 6m |

Stainless Steel As Cast Billets

| As Rolled Straight Length Bars | |

| Round | 15mm to 200mm |

| Round Cornered Square | 50, 55, 60, 63, 75, 80, 95, 98 mm |

Stainless Steel As Ingots

| Ingot Size (mm) | Wt (MT) |

| 290 X 445 X 1700 | 1.8 MT |

| 323 X 412 X 1700 | 2.7 MT |

| 480 X 637 X 1700 | 4.2 MT |

Stainless Steel Rebars

| Condition | Size Range | Size Range |

| As rolled | 6, 8, 10 mm | Coils |

| As rolled and descaled | 12 – 32 mm |

Straight length Bars, Length 12 Mtr. |

Stainless Steel Wire Rods

| Hot Rolled Annealed and Pickled Wire Rods* | |

| Coil Weight | 900 kgs to 1500 Kgs |

| Coil ID | 850 mm min. |

| Coil OD | 1250 mm max. |

| Size Range | 5.5- 38 mm Dia – Rounds 13.3 – 27.5 mm A/F Hexagons |

Stainless Steel Round Edge Flat Bars

| Width | 50 mm minimum 150 mm maximum |

| Thickness | 5 mm minimum 28 mm maximum |

QMS Certification and Approvals

The guiding Philosophy in Sunflag Steel is enhancing customer satisfaction through continual improvemnet.

To continuously achieve higher level of performance in these areas sunflag had adopted and effectively implemented various Quality Management system

| OMS system | Scope | Certification Body |

| ISO 9001 | Complete plant operation | Ul D0S Germany |

| IATF 16494 | Complete plant operation | TUV Nord, Germany |

| AD 2000 – MerkblattWO | Pressure equipment directives | TUV NORD, Germany |

| ISO 14001 | Environmental management certification | TUV NORD, Germany |

| ISO 45001 | Occupational Health & Safety Management systems | TUV NORD, Germany |

| NABL Certification | Sunflag chemical & mechanical laboratories | NABL India |

Process Route

Stainless steel is steel containing 10.5% or more of chromium, which imparts it with corrosion resistant properties, by the formation of an impervious layer of chromium oxide.