Quality Requirement for Free Cutting Steels

- Uniform distribution of MnS

- Hardness

- Microstructure

- Dimentional quality

- Straightness

Typical Co-Relation of Machining Parameters With Elemental Levels

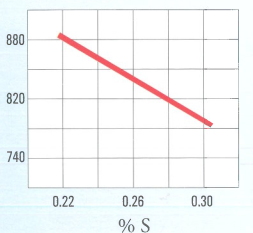

Machining (Force) Torque

Effect of ‘s‘ content on the machining torque.

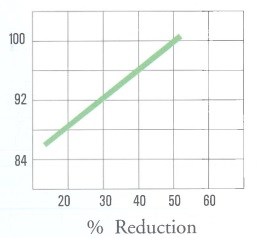

Surface Hardness HB

Free machining steels are generally used after cold processing such as drawing, peeling, grinding etc. The extent of cold work employed in converting black bar of free machining steel into bright bar, decides its surface hardness,which in turn is responsible for its machining performance.

Certification of Quality

- Surface condition : Free from defects

- Macro etch test (ASTM: E-381)

- Spark/Spectral test — 100% bars

- As rolled hardness – Free Cutting Steels <150 BHN

- Inclusion rating – (ASTM – E-45) 2.5 max each – B, C,D

- Micro structure – Sulphide morphology (Aspect Ratio)

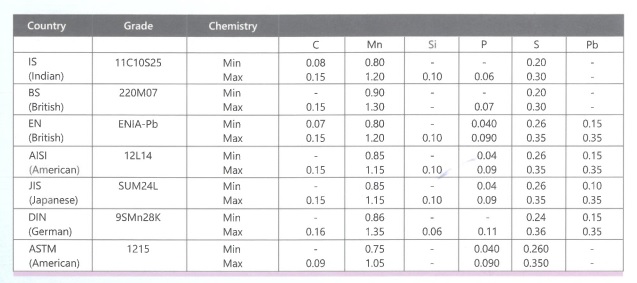

International Specifications of Free Cutting Steels

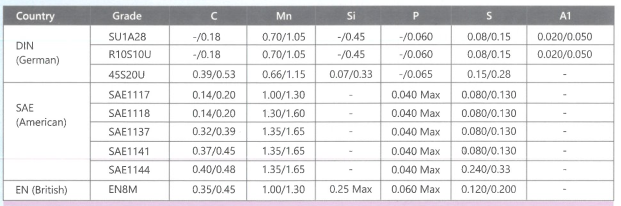

International Specifications of Semi Free Cutting Steels

Sizes and Conditions of Supply

| Condition of Supply | Shapes | Sizes |

|

1. Black |

Hex | 15.5 mm — 38 mm A/F |

| 2. Black | Round | 5.5 mm — 100 mm dia |

| 3. Black | WRD | 5.5 mm — 38 mm dia |

| 4. Drawn | Hex | 14 mm – 36 mm A/F |

| 5. Drawn | Round | 10mm — 50 mm die |

| 6. Peeled & Ground | Round | 10 mm — 90 mm dia |

Free machining steels are generally used after cold processing such as drawing, peeling, grinding etc.