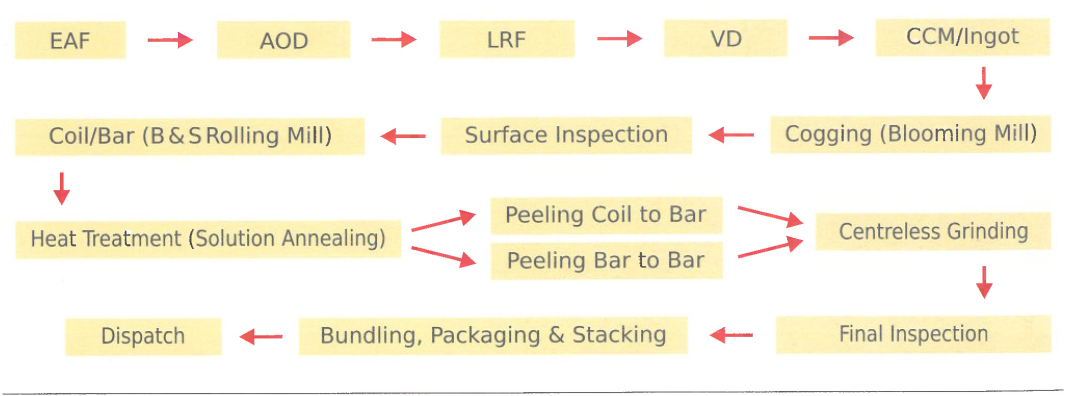

MANUFACTURING ROUTE OF

ENGINE VALVE STEELS

Martensitic Grades

Austenitic Grades

Inspection and Testing

- Surface Quality by M.P.I/ Zyglo/ECT

- Internal Soundness by Ultrasonic Testing

- Dimension & Length Controls

- Metallurgical Testing (Hardness, Microstructure. Inclusion, Grain Size etc.)

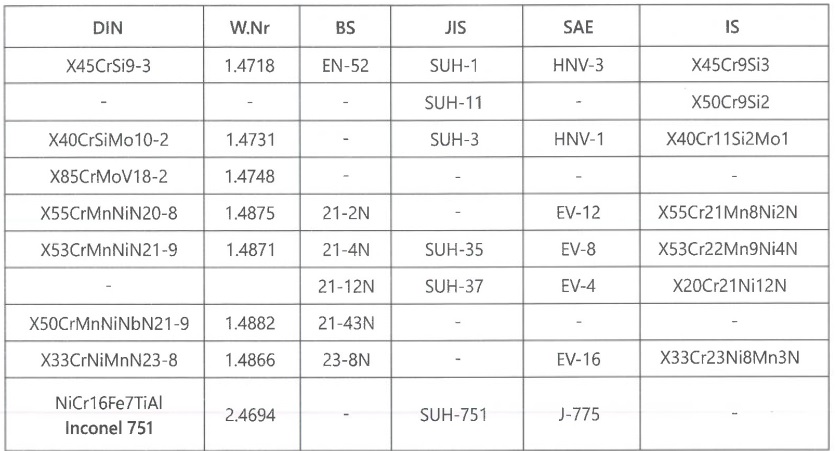

International Standards of Valve Steels

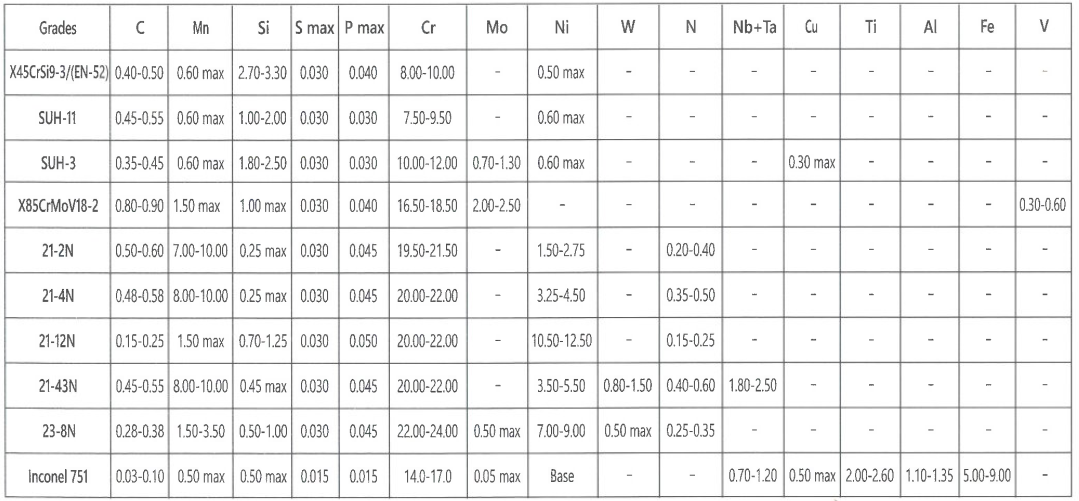

Chemical Composition

Product Details

| Size Range : | |

| Bright Bars | Dia 5.00 mm to 100 mm |

| Hot Rolled Annealed Wire Rod | Dia 5.50 mm to 38 mm |

| Hot Rol. Annealed Bars | Dia 15 mm to 160 mm |

| Standard Length | 4000+50/-00 mm or as per Customer Specified Length |

| Supply Conditions : | |

| Dimensional Tolerance: ISO h9, h11, +0.05/-0.00, +0.05/-0.05, + 0.10. Black Bar as per IS-3739 | |

| Martensitic Grades | Hot Rolled, Annealed or Hardened &Tempered |

| Drawn &Ground, Peeled &Ground and Black bar | |

| Austenitic Grades | Hot Rolled, Solution Annealed, Peeled &Ground and Black Bar |

Mechanical Properties

| Grade | Condition | Yield Strength N/mm2 | Tensile Strength N/mm2 | % Elongation min | % Reduction in Area min | HRC |

| EN-52/X45CrSi9-3 | H & T | 700 | 900-1100 | 14 | 40 | 25-35 |

| SUH-11 | H &T | 700 | 900-1100 | 14 | 40 | 25-35 |

| SUH-3 | H &T | 700 | 900-1100 | 14 | 40 | 25-35 |

| X85CrMoV18-2 | H &T | 800 | 1000-1200 | 7 | 12 | 25-35 |

| 21-2N | Solution Annealed | 550 | 900-1150 | 8 | 10 | 30-40 |

| 21-4N | Solution Annealed | 580 | 950-1200 | 8 | 10 | 30-40 |

| 21-12N | Solution Annealed | 400 | 800-1200 | 35 | 45 | 23-25 |

| 21-43N | Solution Annealed | 580 | 950-1150 | 10 | 12 | 30 min |

| 23-8N | Solution Annealed | 550 | 850-1100 | 25 | 30 | 26 min |

| Inconel 751 | Solution Annealed | 630-850 | 1100-1300 | 12 | 20 | 32-40 |

Bearing steels are special class of low alloy steels, typically with 1% carbon and 1.4% chromium. Manganese and Molybdenum are added in certain special cases.