Material quality requirements for cold heading steels

- Excellent surface quality ensuring zero-defect situation so that forged components have no defects

- Good control over ovality to ensure smooth forging process.

- Good control over mechanical properties such as tensile strength and reduction is to ensure proper cold forgeability and productivity

- Completely descaled surface to avoid forging defects such as scale pits and resultant surface roughness.

- Suitable metallurgical structure to ensure proper machinability level.

- Good and uniform response to heat treatment since the components are always treated in bulk.

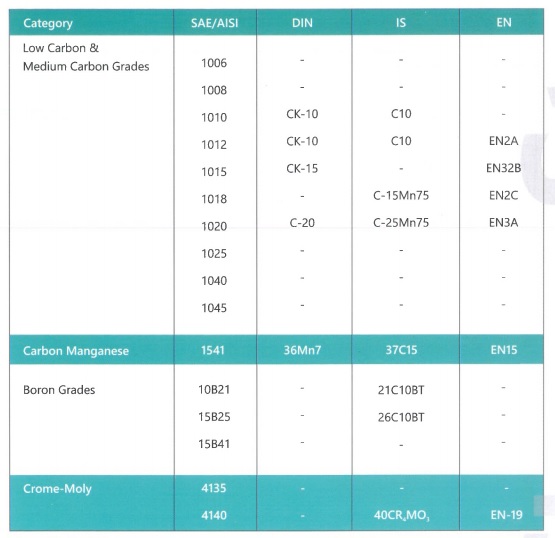

| Category | SAE/AISI | DIN | IS | EN |

| Low Carbon & Medium Carbon Grades | 1008 | – | – | – |

| 1010 | CK-10 | C10 | – | |

| 1012 | CK-10 | C10 | EN2A | |

| 1015 | CK-15 | – | EN32B | |

| 1018 | – | C-15Mn75 | EN2C | |

| 1020 | C-20 | C-2SMn75 | EN3A | |

| 1025 | – | – | – | |

| 1040 | – | – | – | |

| 1045 | – | – | – | |

| Carbon Manganese | 1541 | 36Mn7 | 37C15 | EN1S |

| Boron Grades | 10B21 | – | 21C10BT | – |

| 15B25 | – | 26C1OBT | – | |

| 15B41 | – | – | – | |

| Crome-Moly | 4135 | – | – | – |

| 4140 | – | 40CR4MO3 | EN-19 |

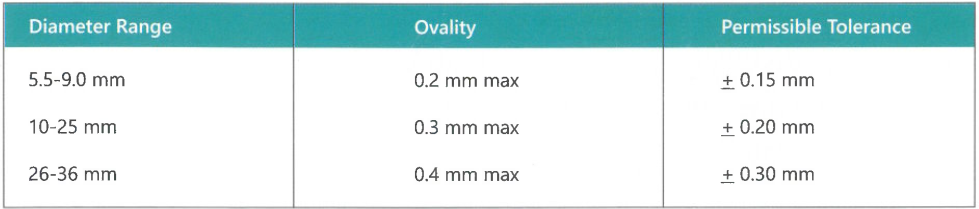

Dimensional Specifications (As rolled)*

| Diameter Range | Ovality | Permissible Tolerance |

| 5.5-9.0 mm | 0.2 mm max | ± 0.15 mm |

| 10-25 mm | 0.3 mm max | ± 0.20 mm |

| 26-36 mm | 0.4 mm max | ± 0.30 mm |

* In specific cases stricter specifications can be met.

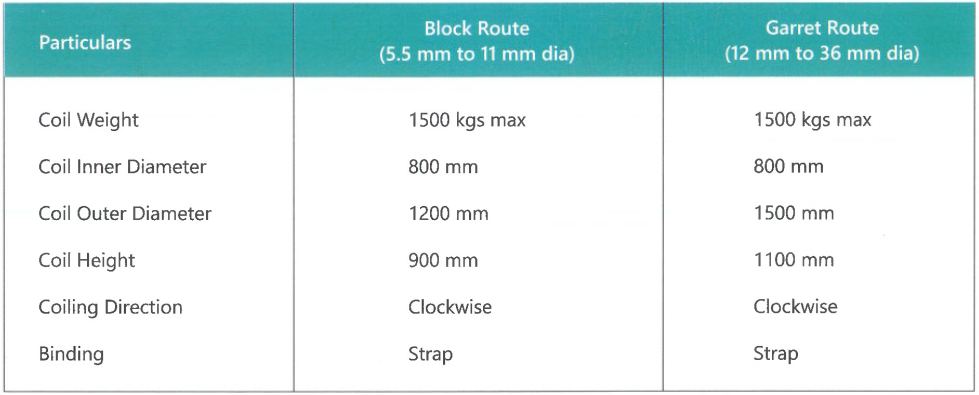

| Particulars | Block Route (5.5 mm to 11 mm dia) | Garret Route(12 mm to 36 mm dia) |

| Coil Weight | 1500 kgs max | 1500 kgs max |

| Coil Inner Diameter | 800 mm | 800 mm |

| Coil Outer Diameter | 1200 mm | 1500 mm |

| Coil Height | 900 mm | 1100 mm |

| Binding | Strap | Strap |

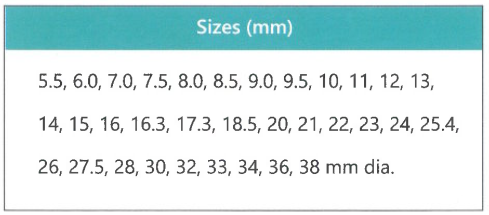

Wire Rods Rolled Sizes :

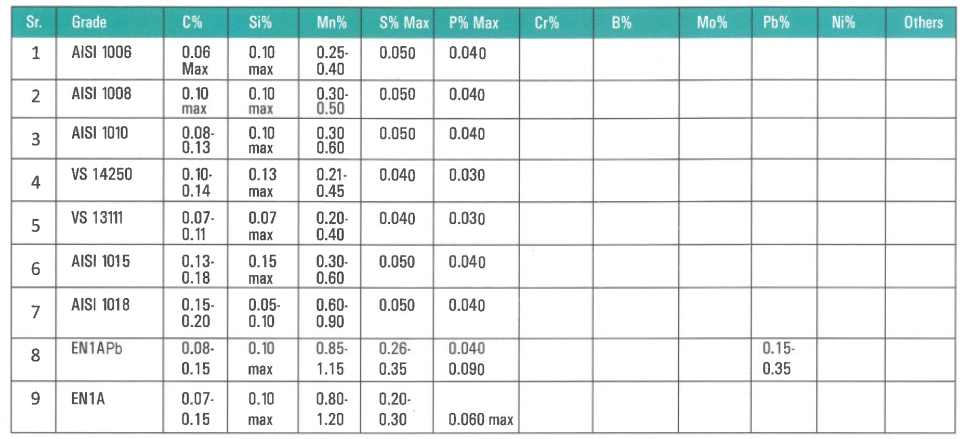

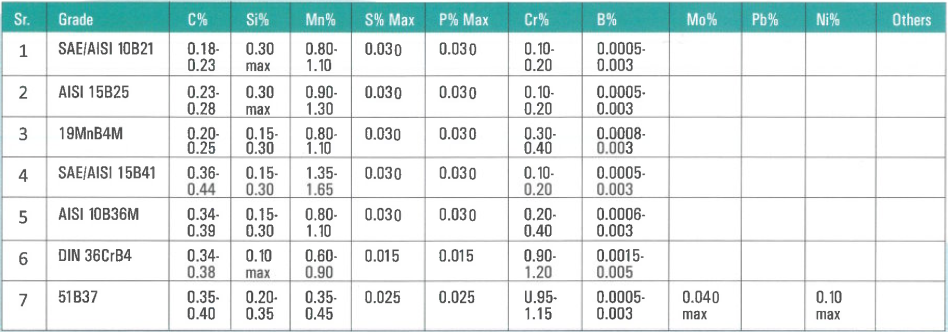

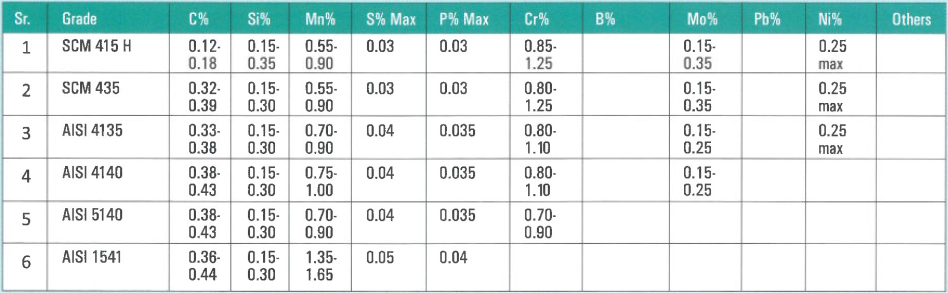

CHEMICAL COMPOSlTIONS or TYPICAL COLD FORGING QUALITY GRADES :

CARBON STEELS

BORON STEELS

ALLOY STEELS

Bearing steels are special class of low alloy steels, typically with 1% carbon and 1.4% chromium. Manganese and Molybdenum are added in certain special cases.